Equipment qualification is the procedure to “confirm, that the equipment is capable of meeting, throughout its operation life, the requirements for performing safety functions while subject to the environmental conditions (e.g. vibration, temperature, pressure, jet impingement, radiation, humidity) existing at the time of need. These environmental conditions shall include the variations expected during normal operation, anticipated operational occurrences and accident conditions.”

"Equipment Qualification in operational nuclear power plants: Upgrading, preserving and reviewing“ - IAEA; Safety Reports Series No.3

EQ is an integral part of the equipment life cycle to ensure the quality of the equipment and its safety function on demand.

This includes complex processes such as e.g. functional checks, aging evaluation, environmental compliance, survivability to seismic events, radiation robustness and operation during postulated initiating events / design basis accidents and may be proven by

- Type testing

- Operating experience

- Analysis

- Combined methods

Where the preferred approach is type-testing.

Mirion has more than fifteen (15) years of experience in preparation, realization and conservation of international qualification campaigns in the nuclear market, including qualification of various types of sensors, detectors, cables, I&C equipment, electrical components and transducers as well as on complete gamma radiation monitoring systems, neutron flux monitoring system including electrical cabinets complying to highest demands (Class 1E equipment, Software category A).

Equipment qualification at Mirion is performed by an independent Equipment Qualification (EQU) team.

In order to standardize the EQ process, Mirion has implemented a dedicated qualification process including three process phases – as also proposed by IAEA Safety Standard SSG-69 “ Equipment Qualification for Nuclear Installations” as follows:

Phase 1 - Qualification preparation This phase defines all needed inputs required for qualification testing and specifies the test severities and test realization details to comply with customer requirements and the required standards.

Phase 2 - Qualification testing All practical testing or analysis, including full results documentation as reuqired by standards is realized.

Phase 3 - Qualification completion All test results are summarized and arranged in a structured and traceable way.

Mirion is experienced to test and comply to various national and international regulatory framework requirements for safety related and non safety related equipment such as e.g.

IEC / IEEE 60780-323 |

IEC 60068-2 series |

KTA 150x series |

IEC / IEEE 60980-344 |

IEC 61000-4 series |

KTA 350x series |

RG 1.89 |

IEC 60532 |

RCC-E |

RG 1.180 |

IEC 60951 series |

NF M64-001 |

EPRI TR 102323 |

IEC 60515 |

|

Testing on equipment under test (EUT) is done either in-house or externally in suitable accredited laboratories with relevant test parameters traceable to a national standard and may include

- Initial / functional tests

- Environmental tests

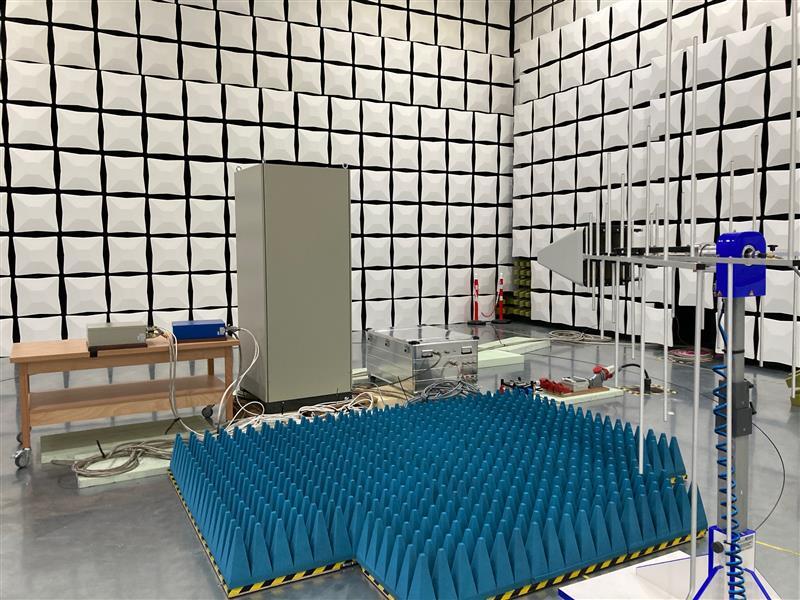

- EMI/RFI tests

- Nuclear test (in radiation test laboratories or test reactors)

- Aging tests (thermal, radiation, wear)

- Vibration & Shock tests

- Seismic tests

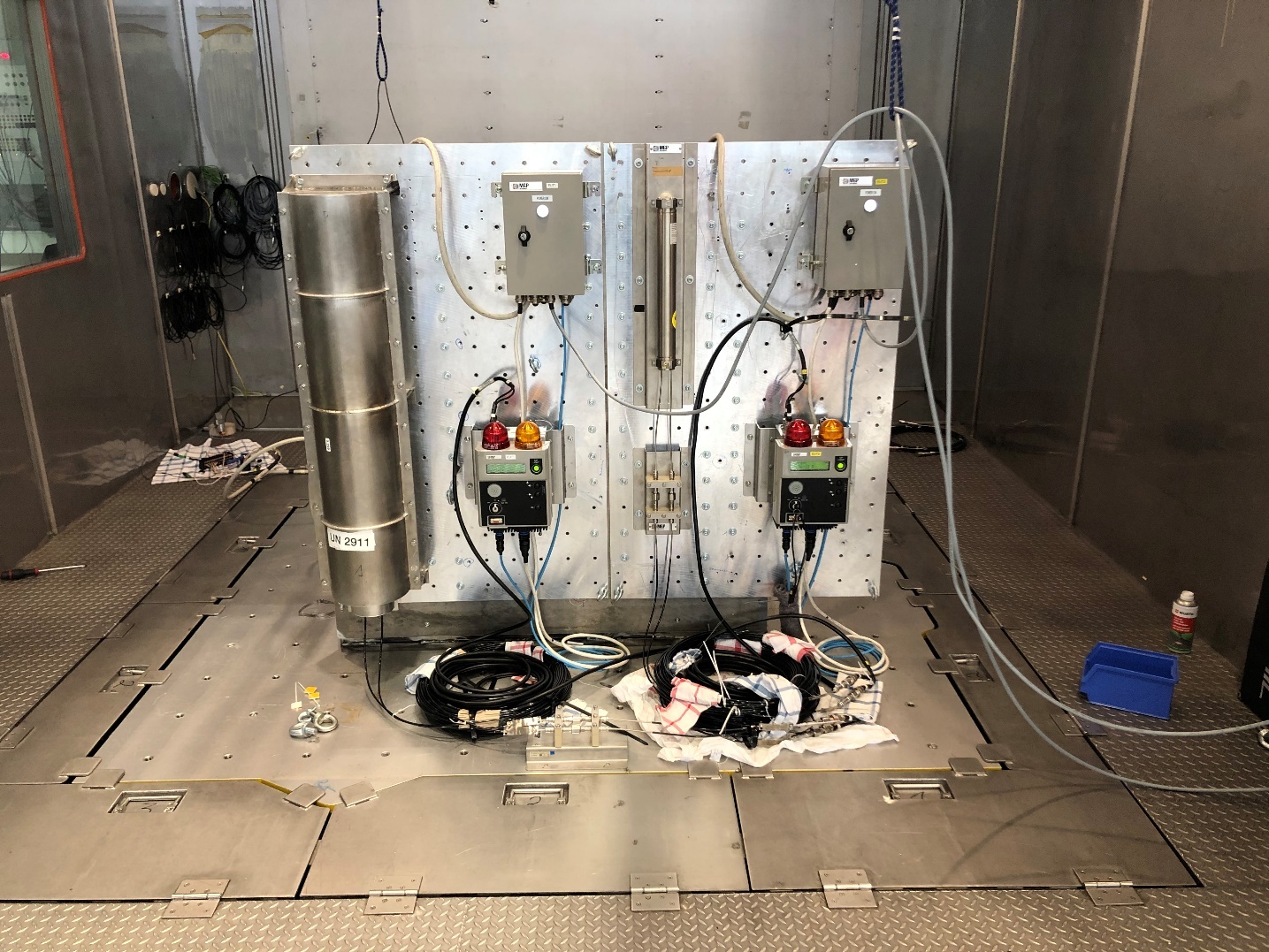

- DBA tests (e.g. LOCA, HELB, accident radiation, submergence, chem. spray)

- Severe Accident tests

We provide customized qualification services to meet your specific requirements.

For further information please contact us and we’ll be happy to support your project / qualification tasks.

|  |

Nuclear tests | |

|  |

Seismic tests | EMI tests |