Chrysos Corporation Uses Mirion Detectors for Groundbreaking Minerals Analysis Technology

Chrysos PhotonAssay™ is Revolutionizing the Global Mining Industry

For centuries, the use of extreme heat and chemical reagents has been the most common method of assaying gold and other precious metals in the mining industry. Now, with the help of Mirion Technologies, mining technology company Chrysos Corporation is changing the game. Exemplifying the potential Mirion products have for applicability outside the nuclear industry, Chrysos is leveraging Mirion HPGe detectors to deliver its faster, safer, more accurate and environmentally friendly PhotonAssay™ technology around the globe.

How does it work?

Until now, the mining industry has relied on fire assay to separate and extract precious metals from mineral slag. This process uses extreme heat and acid, and requires trained operators to perform quality assurance.

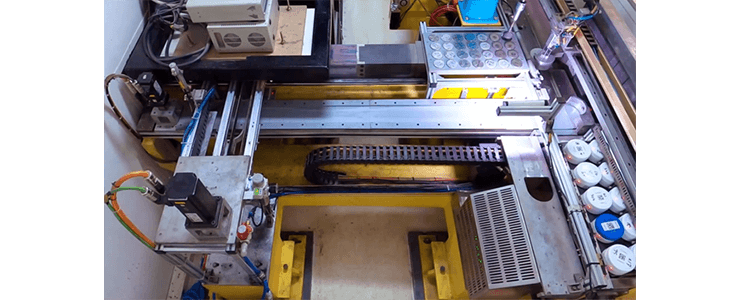

In contrast, Chrysos PhotonAssay™ units are fully automated and do not require specifically skilled operators. First, samples are crushed and loaded into polymer jars.

Then, they are paired with a control reference and exposed to high-energy X-rays.

These X-rays activate any gold atoms that may be in the sample, causing them to emit a unique gamma-ray signature. The sample is then transferred via robotic shuttle to the detection setup.

Here, Mirion HPGe detectors measure the gamma-ray signatures to analyze the metal concentration in the sample. The entire process takes as little as two minutes per sample.

What are the advantages of Chrysos PhotonAssay™ Technology?

Faster process

The PhotonAssay™ unit’s process is significantly faster than fire assay due to several efficiency-boosting factors. Without the use of chemical reagents, the process has fewer preparation requirements. While traditional assay preparation includes time-consuming sample pulverization and chemical treatment, the PhotonAssay™ unit only requires the sample to be crushed. From there, the operator just presses a “start” button, and the unit does the rest.

Safe and sustainable

Fire assay uses chemicals that produce toxic waste that is dangerous for both operators and the environment. In comparison, PhotonAssay™ samples are analyzed with X-rays inside a shielded container and can be safely handled again shortly after the process is completed. This also means fewer CO2 emissions.

Cost effective

With fire assay, samples are typically destroyed in the process. Chrysos PhotonAssay™ technology keeps the samples intact so they can be retained for further analysis and quality control if necessary. The enhanced efficiency of this process does not sacrifice accuracy or sensitivity. Also, because the process is fully automated, fewer operators are required.

Going beyond radiation detection

Using Mirion technology this way, Chrysos has highlighted the potential that radiation detection instruments have for expanding into other industries. The PhotonAssay™ unit can detect more than half of all naturally occurring elements, meaning that it has use in non-gold markets as well.

We are excited to see our time-tested Mirion HPGe detectors opening doors to companies like Chrysos, and we look forward to what’s to come.

Questions?