Lab Experiment 11: Mathematical Efficiency Calibration

Purpose:

- To demonstrate how to use mathematical modeling to do efficiency calibrations and to verify the result with a radioactive source.

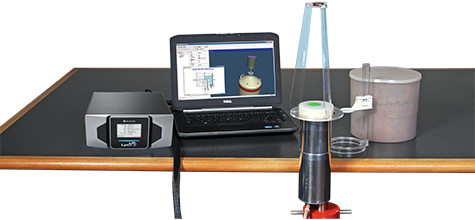

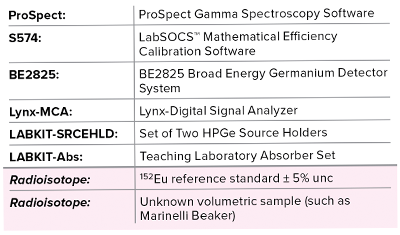

Equipment Required:

Theoretical Overview:

Measuring the efficiency with sources requires an inventory of sources that matches the geometries that are being measured. It is possible to acquire sources of common laboratory geometries, for example liquid solutions for beakers or epoxy matrices for Marinelli beakers. But there are geometries that are not practical to manufacture with sources or there may be cases of odd-shaped sources that are only going to be measured a few times or when parameters of the sample are different from the calibration source. In all of these cases, mathematical calibrations can be used instead, such as Monte-Carlo simulation (e.g. Monte Carlo N-Particle eXtended [MCNPX] transport code) or the LabSOCS (Laboratory SOurceless Calibration Software) and ISOCS (In-Situ Object Counting Systems) methodology. The interaction of photons with matter and its cross sections is well known and is tabulated for all naturally-occurring atoms for a wide range of energies. See Figure 11-1 and Experiment 3.

Using the equation:

the attenuation of photons passing through a material of length x can be calculated. The attenuation of photons for a particular energy originating from a point in space directed to a point on the detector can be calculated from the cross sections, the densities, the atomic composition and the path length through all the materials between the point and the detector. This method, utilized by LabSOCS and ISOCS software, is called ray tracing. In order to calculate the efficiency for the point it is also necessary to know the efficiency of the point without the materials, i.e., in a vacuum. With all of these parameters known it is possible to calculate the efficiency for this point in the measurement scenario. Points are generated uniformly in the radioactive part of the geometry and the efficiency is calculated for each of these points. The efficiency for the whole sample is the average of these points. When additional points are generated the sample efficiency will converge and the calculation finishes.

One of many benefits of mathematical modeling is that it is easy to refine the model if the sample does not agree with the modeled geometry. For example if the fill height of a beaker is not the same as the modeled fill height, the model can change to accommodate the difference. This contrasts a source-based calibration, where either the reference source or the sample measurement geometry must be physically modified, or the uncertainty in the sample activity must be increased significantly to accommodate the bias introduced by the discrepancy between the reference source and the sample. All other parameters can be changed in a similar manner for modeled efficiencies.

Figure 11-1: Linear attenuation coefficient of photon interaction in iron as a function of energy.

Introduction to LabSOCS software (Mathematical Efficiency)

LabSOCS and ISOCS software require that the detector to be used has been characterized by the detector manufacturer; the characterization is based on high-precision measurements and simulation optimization. This provides the vacuum-point efficiencies unique to each detector, and the calibration software then determines the attenuation correction for the specific measurement geometry. LabSOCS and ISOCS software include a number of source templates to choose from such as point source, sphere, cylinder, beaker, box, etc.

The user selects a template geometry, determines the relevant physical dimensions, and identifies a range of energies to calculate efficiency values. Figure 11-2 shows a picture of the different source geometries available in LabSOCS software. Table 11-1 shows a typical listing of the energies and efficiencies from LabSOCS software while Figure 11-3 shows a typical efficiency graph based on the values in the table. Refer to References 9 and 10 on Page 77 for more information on setting up and executing LabSOCS geometries.

Figure 11-2: Selection of LabSOCS sample geometry templates.

For an efficiency calibration to be accurate it is critical that the geometry used to generate the efficiency agrees with the geometry of the sample count. For mathematical modeling this means that the model created needs to resemble as closely as possible the measured sample. This includes the dimensions of the detector, the sample, any absorbers or collimators, the material composition and density. Extra care should be taken to accurately model the materials between the source and detector and the location of the source and materials (particularly close to the detector where the efficiency is sensitive to small changes in location). Many commonly-used beakers don’t have flat bottoms but a slightly curved bottom. If the sample is positioned directly on the endcap and the bottom of the beaker is not accurately modeled then this can lead to significant bias in the calculated efficiency and therefore the final measurement result. Parts of the sample that are not directly between the radioactive part of the geometry and the detector crystal do not influence the peak efficiency and therefore do not require as much attention.

Table 11-1: LabSOCS calculated efficiencies for a point source at 20 cm from the surface of a 2x2 NaI detector.

Figure 11-3: Modeled efficiency for a 2x2 NaI detector with a point source located 20 cm from the endcap.

Experiment 11 Guide:

Exercise 1

1. Using LabSOCS software, replicate the germanium detector experimental set up of Experiment 8 and extract the efficiency values.

2. Plot these in Excel or another graphing application.

3. Compare the modeled efficiency curve with the measured efficiency curve from Experiment 8. Comment on any differences.

4. Estimate the uncertainties in the measured efficiency (statistical uncertainty and certificate uncertainty). See the LabSOCS manual for the modeled uncertainties. Do the measured and calculated efficiencies agree within the uncertainties? If not measure the dimensions of the sample again and refine the model.

Exercise 2

1. Ensure that the Lynx II DSA (with the HPGe detector connected) is connected to the measurement PC either directly or via your local network.

2. Using the adjustable source holder, place the 152Eu reference standard at a distance of about 20 cm from the endcap of the high-purity germanium detector. Record this distance. Remove any material between the source and detector before counting. Place one of the materials from the absorber kit between the source and the detector.

3. Open the ProSpect Gamma Spectroscopy Software and connect to the Lynx II DSA.

4. Configure the MCA settings as recommended in Experiment 7.

5. Use the software to apply the recommended detector bias to the HPGe detector.

6. Set the PHA conversion gain to 32768 channels.

7. Adjust the coarse and fine gain of the MCA such that the 1408 keV peak is visible in the upper part of the spectrum.

8. Acquire data, ensuring that at least 10 000 counts are achieved in several of the major peaks throughout the spectrum. Use the spreadsheet to calculate the energy calibration coefficients. Enter these into the ProSpect software using the Energy Calibration tab.

9. Measure the net peak area and uncertainty for each of the major peaks. Calculate the ratio of count rates for each peak to the count rates for the data collected in Experiment 8.

10. Model the experiment set up of Step 2 in LabSOCS Geometry Composer and extract the efficiency values. Calculate the ratio of the efficiency values for this geometry to the efficiency values extracted in Exercise 1. How do these compare to the ratios calculated in Step 9?

Exercise 3

1. Place a volumetric sample of unknown activity on the germanium detector.

2. Count the sample for enough time to collect 10 000 counts in several significant peaks. Measure the net peak area and uncertainty for each of the major peaks, and identify candidate nuclides in the sample.

3. Using LabSOCS Geometry Composer, identify a template that is consistent with the measurement geometry. Measure the physical parameters and input them into LabSOCS software. Extract the efficiency results.

4. Use the LabSOCS efficiency results, the peak area counts, and known photon intensities for the candidate nuclides, calculate the activity of the nuclides in the sample. Discuss the possible sources of error and uncertainty.

Exercise 4

1. In LabSOCS Geometry Composer create a model of a volumetric sample (such as the simple beaker template) on the detector endcap or use the one from the previous exercise and calculate the efficiency for a range of photon energies.

2. Calculate the efficiency of the same sample in Step 1 but at a distance of 10 cm from the detector.

3. Calculate the efficiency of the same sample in Step 1 but at a distance of 10 cm from the detector and with an absorber between the sample and the detector.

4. Compare the three modeled efficiencies to the two measured efficiencies for a low-, a medium- and a high-energy peak. For the different energies which is the most important parameter, the source-to-detector distance or the materials between the source and the detector?

5. In one of the models created decrease the fill height of the sample by 50% and calculate the efficiencies. Then compare it with the original model for a high-, medium- and low-energy peak. For which energy does the efficiency change the most? Explain the result.